LVT Flooring

- Home

- LVT Flooring

What is LVT Flooring ?

The Size Of LVT Flooring

Standard Size

-

4"*36"

(101.6*914.4mm) -

6"*36"

(152.4*914.4mm) -

12"*12"

(305*305mm) -

18"*18"

(457.2*457.2mm)

Other Size

-

6"*18"

(152.4*457.2mm) -

7"*48"

(177.8*1219.2mm) -

9"*48"

(228.6*1219.2mm) -

18"*36"

(457.2*914.4mm)

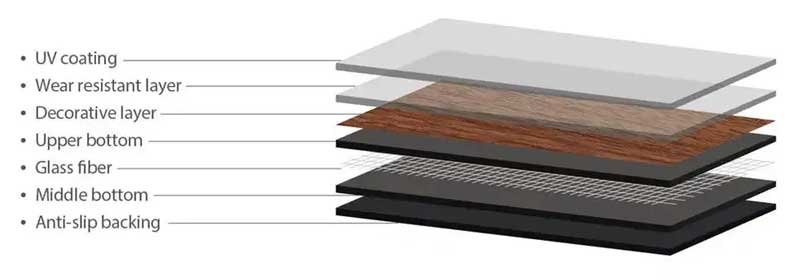

The Structure Of LVT Flooring

1. UV layer (UV coating): UV oil cured by the curing agent to form the coating, can prevent ultraviolet radiation on the volatilization of chemical substances within the plate.

2.Wear layer (Wear layer): PNC transparent wear layer,

thickness of about 0.2-0.5mm, transparent texture, strong

adhesion, wear and scratch resistance, wear resistance factor of up to 6000-8000 rpm.

3. Color film layer (Printing film): a variety of wood grain, stone grain, carpet grain decorative layer, can meet the different occasions, different tastes of different needs.

4. Polymer substrate layer (Polymer substrate layer): by the stone powder and thermoplastic polymer materials in the mixing of homogeneous and then extruded at high

temperature made of composite panels, both wood and

plastic properties and characteristics, so the floor has good strength and toughness.

5. Silent pad (IXPE/EVA silent cotton)) (can be added or not)

Back Of LVT Flooring ( Luxury Vinyl Tile)

Hot Colors - Colors Can Be Customized

Carprt SPC Flooring

Stone Pattern SPC flooring

Wood Grain SPC Flooring

LVT Flooring Applications

1.Education system (including schools, training centres, kindergartens, etc.)

2.Health care system (including hospitals, laboratories, pharmaceutical factories, nursing homes, etc.)

3.Commercial system (including shopping malls, supermarkets, hotels, entertainment and leisure centers, catering industry, specialty stores, etc.)

4.Sports systems (stadiums, activity centres, etc.)

5.Office system (office building, conference room, etc.)

6.Industrial systems (factory buildings, warehouses, etc.)

7.Transportation system (airport, train station, bus station, wharf, etc.)

8.Home system (family room, bedroom, kitchen, balcony, study, etc.)

What are the production processes of LVT flooring?

1. Raw material preparation: Prepare raw materials such as PVC resin, quartz, mineral powder, stabilizer, etc. according to production needs.Mix the raw materials in a certain proportion to ensure that the performance of the flooring material meets the standard requirements.Put the prepared raw materials into the mixer for stirring to ensure that all raw materials are fully mixed and evenly mixed.

2. Material extrusion: The mixed materials are extruded through an extruder to form the floor blank.

3. Cooling: The extruded floor blank is cooled by a cooling device to solidify it.

4. Embossing: Use an embossing machine to emboss the floor blank to produce a floor surface with wood grain texture.

5. Cutting: Cut the embossed floor blank to make it a standard size floor.

6. UV coating treatment: Apply UV wear-resistant layer and anti-fouling layer on the surface of the floor to increase the durability and easy cleaning of the floor.

7. Plastic sealing: The floor is plastic sealed by a plastic sealing machine to make the surface smoother and increase wear resistance.

8. Inspection: The quality of the produced floor is inspected to ensure that the floor meets the relevant standards.

9. Packaging: The floor is packaged, usually using packaging materials such as cartons to ensure that the product is not damaged during transportation.

10. Storage and sale: After the floor is packaged, it is stored in the warehouse waiting for sale and distribution. The above is the process flow of LVT flooring. Each step requires strict control and quality supervision to ensure that the quality and performance of the floor meet market demand. With the development of technology and changes in demand, the production process of LVT flooring is also constantly innovating and improving to meet consumers’ requirements for the beauty and practicality of flooring.

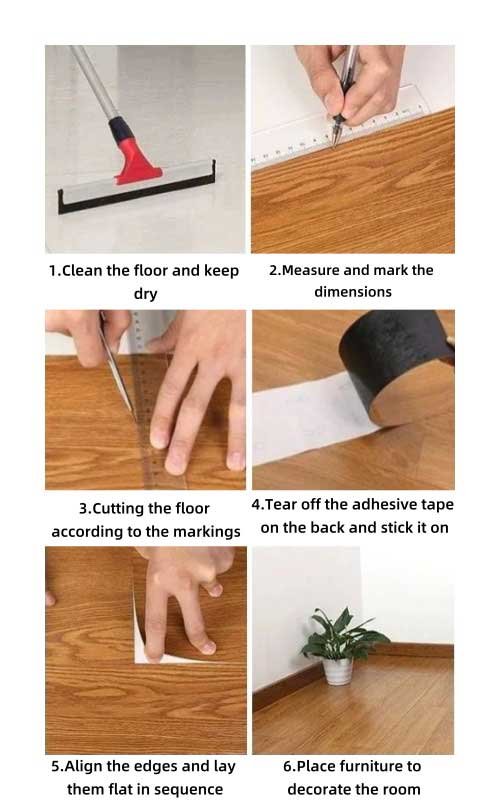

The floor of LVT (Luxury Vinyl Tile) is a kind of advanced vinyl floor, and the installation process is relatively simple. The following are the general installation steps of LVT floor:

1. Preparation:– Ensure the floor is flat, dry, clean, and free of protruding nails or other obstacles.

– If necessary, repair and polish the floor first.

2. Measurement and layout:

– Use measurement tools to measure the size of the room to determine the amount of floor needed.

– According to the shape and size of the room, plan the laying direction of the floor and mark it on the ground.

3. Floor preparation:

– Open the floor packaging and let the floor adapt to the temperature and humidity in the room, usually for 24 hours.

– Inspect the floor to ensure there is no damage or defect.

4. Installation of the floor:

– Start from one corner of the room and place the first floor tile on the ground according to the laying direction.

– Use installation tools (such as a rubber hammer and installation blocks) to ensure the seams between the floor tiles are closely fitted.

– Use a specific installation method (such as snap-lock, adhesive, or dry adhesion) to install the floor to the ground.

5. Cutting and trimming:

– If necessary, use a saw or cutting tool to adjust the floor to fit the shape of the room edges and obstacles.

– At the door or other places, use transition strips or decorative strips to cover the transitions between the floors.Frequently FAQ

FAQ

1. What are the benefts of LVT flooring ?

LVT flooring has various styles, and the imitation materials are exquisitely made and lifelike, such as wood grain, stone grain, brick grain and other natural and non-repetitive textures.

1) Green and environmentally friendly, formaldehyde-free

The main raw material of LVT flooring is luxury vinyl resin, which is natural and environmentally friendly, 100% free of formaldehyde, lead, benzene, heavy metals and carcinogens, no soluble volatiles, and no radiation.

2) Waterproof, moisture-proof, anti-slip, antibacterial and mildew-proof LVT’s main raw material ethylene has no water affinity and will not mold in a humid environment; the wear-resistant layer has special anti-slip properties, and it will become astringent when

it comes into contact with water, and it is not easy to slip. The surface layer will have antibacterial and anti-fouling treatment, which can inhibit the reproduction of bacteria. It can be used

in most indoor spaces and has a wide range of applicability.

3) Good thermal conductivity, the first choice for floor heating, comfortable foot feel, and elastic LVT flooring has good heat dissipation and thermal conductivity, and floor heating conducts heat evenly and quickly, making it the first choice for floor heating. Moreover, LVT flooring is

very comfortable and elastic, which can disperse the pressure on the soles of the feet and can also recover elastically under the impact of heavy objects.

4) Super wear-resistant, flame-retardant, long service life, and wide range of applications

The surface has a transparent wear-resistant layer that has been processed by high technology, with a wear-resistant revolution of about 9000. Depending on the thickness of the wearresistant layer, it can be used for 10-50 years. The fire-retardant performance is also very good, it cannot spontaneously combust, and combustion does not produce toxic and harmful

gases, which is also very suitable for public spaces.

5) Fashionable colors, many styles, and three-dimensional scratches The colors of LVT floors are the latest popular fashion styles in the past two years. There are many colors to choose from, and there are three-dimensional scratches on the surface, which completely simulates solid wood floors.

6) Easy installation and maintenance The installation and maintenance of LVT floors are very convenient, without spending too much manpower and financial resources.

7) Fire-retardant The fire resistance index of qualified LVT floors can reach B1 level.

As LVT products become more mature, and the thickness of the specifications can be spliced with the square carpet without any gap, it can better meet the needs of more spaces.

2. What is the difference between LVT floor and SPC floor ?

Both LVT floor (Luxury Vinyl Tile) and SPC floor (Stone Plastic Composite) are a type of plastic floor, but there are some differences in their structure, composition and performance.

1. Structure and composition:

– LVT floor: LVT floor is usually composed of a multi-layer structure. The top is a protective layer, below it is a pattern layer and a PVC layer, and the bottom is a base layer. The pattern layer of LVT floor imitates natural materials such as wood grain and stone grain through printing technology.

– SPC floor: SPC floor is composed of stone plastic composite material. Its structure mainly includes stone plastic composite material layer, texture layer, UV coating and base layer.

2. Material composition:

– LVT floor: The PVC layer of LVT floor is mainly made of polyvinyl chloride (PVC). The pattern layer can use different types of printing technology and texture design to imitate natural materials such as wood and stone.

– SPC floor: The main component of SPC floor is stone plastic composite material, which is a mixture of stone powder, polyvinyl chloride (PVC) and other additives. This makes SPC flooring stronger, more stable and has a higher compression resistance.

3. Stability and durability:

– LVT flooring: Due to the construction and materials of LVT flooring, it is relatively soft and sensitive to unevenness of the ground. It is suitable for low to medium traffic areas and is suitable for family homes, commercial spaces and light commercial use.

– SPC flooring: SPC flooring is composed of stone plastic composite materials, so it has excellent stability and durability. It has good performance on uneven ground and is suitable for high traffic areas such as commercial offices, shopping malls and public places.

4. Comfort and sound absorption:

– LVT flooring: Due to the softer material of LVT flooring, it is softer when stepped on, providing a certain foot comfort. But it is relatively thin and has poor sound absorption performance.

– SPC flooring: SPC flooring is firmer and feels harder when stepped on due to its harder stone plastic composite material. However, SPC flooring has good sound absorption performance due to its dense structure, which helps to reduce noise transmission.

5. Waterproof:

– Both LVT and SPC floors have excellent waterproof properties. Their materials and structures enable them to resist moisture penetration and humid environments, making them ideal for use in wet areas such as kitchens, bathrooms, and laundry rooms.

Summary: Both LVT and SPC floors are excellent choices for plastic flooring, and there are some differences in their structure, composition, and performance. LVT floors are more suitable for family homes and light commercial use, while SPC floors are more suitable for high-traffic commercial and public places. Which floor to choose depends on your needs, budget, and space requirements. No matter which floor you choose, they all provide durability, comfort, and beauty, adding comfort and style to your living space.

3.What are the most critical product indicators of PVC flooring ?

1. Stability:

product shrinkage and expansion rate 80℃ 6 hours. 0.25%, 0.15% (industry standard)

2. Heating warpage:

80℃ 6 hours EN<2mm;

Enterprise standard:

1.2mm (dryback);

1.0mm (click);

0.5mm (loose lay)

3. Lock pull: room temperature (23℃) 5.0mm>13-15kgs/5cm.

•4.2mm>12kgs/5cm.

• If V buckle is used on the short side, 4.2mm>15-18kgs/5cm.

4. Peeling strength: the bonding strength between the color film and the middle material

5. Scratch resistance and wear resistance

6. Brightness: 10+/-2.